Case Study - Setting & Testing

Global E & P Company Sets Record

For RIH

Setting packers is a regular activity for many E & P companies across the globe. But, unfortunately, so is the reliance on legacy products to perform this operation.

The challenge

One of Europe's largest E & P companies was seeking a new innovative solution to run upper completion with autofill and without back flow, which would replace an existing flapper valve. The new solution had to achieve all this and increase efficiency and reduce rig time.

The solution

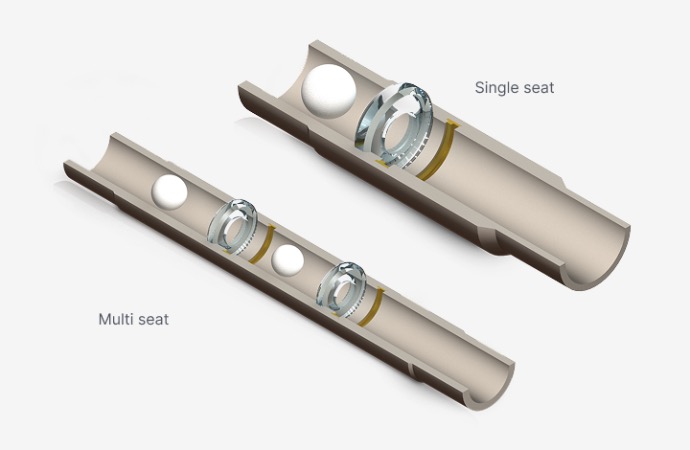

A 4.5” diameter Fantom™ Shatter Ball Seat (SBS) was installed into the tool string as it has all the strength and flexibility needed when setting and testing but comes with the benefits required over the flapper valves previously used.

Once packer setting and tubing testing was completed, the Fantom™ SBS was opened remotely without intervention, resulting in genuine full-bore ID and a reduction in rig time.

The Result

New record set for running upper completion with an average speed of nearly 12 jnt/hr. No need to fill tubing and upper completion run without backflow.

Fantom™ Packer Setting and Tubing Testing

6 standard size

Find the Right Solution for Your Operation

Legacy tools have held back efficiency in well operations for too long. Fantom™ replaces outdated pressure isolation methods with engineered simplicity — glass-based solutions that fully disintegrate, leave no debris, and offer instant full-bore access.

Engineered Simplicity. Trusted Expertise

We’re Glass Technology Experts

Our experience spans decades in well completions, interventions, and cementing — gained inside some of the biggest E&P and service companies. We know your challenges because we’ve lived them. That’s why we took a new approach: innovative glass solutions that deliver well integrity without the baggage of legacy tools

Talk to an Expert

We’re ready to help. Whether you need technical guidance or want to discuss a specific project, our team is just a message away.

Your Questions, Answered

Explore our FAQs to learn more about product performance, installation, standards, and how our glass solutions fit into your operations.