Case Study – Autofill

Major Offshore Operator Increases Efficiency 20%

Offshore wells in HPHT environments demand uncompromising safety, operational reliability, and efficiency throughout the completion phase.

The problem

In a recent Gulf of Mexico project, a leading offshore service provider faced challenges with traditional completion procedures that relied on manual filling of the tubing string during run-in-hole.

This approach not only consumed excessive rig time but also introduced risks associated with fluid handling and uncontrolled influxes.

The solution

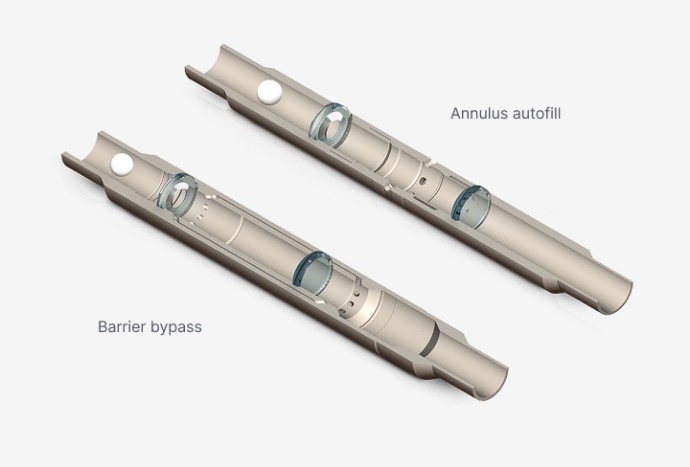

3.5” Fantom™ shatter ball seat (SBS) and barrier combination was installed in an open-port configuration, enabling fluid from the annulus to fill the tubing string naturally during RIH. Once the target depth was reached, a ball was dropped to activate the internal sleeve, closing the ports and establishing upstream pressure integrity which allows effective execution of remaining completion activities.

When completed, the Fantom™ SBS and barrier are easily opened without intervention, resulting in genuine full-bore ID and a reduction in rig time. This dramatically improved efficiency while increasing safety and profitability.

The Result

A massive increase in efficiency and well control generated a reduction in rig time which delivered huge cost savings.

Fantom™ Autofill Barrier Combination

4 standard size

Find the Right Solution for Your Operation

Legacy tools have held back efficiency in well operations for too long. Fantom™ replaces outdated pressure isolation methods with engineered simplicity — glass-based solutions that fully disintegrate, leave no debris, and offer instant full-bore access.

Engineered Simplicity. Trusted Expertise

We’re Glass Technology Experts

Our experience spans decades in well completions, interventions, and cementing — gained inside some of the biggest E&P and service companies. We know your challenges because we’ve lived them. That’s why we took a new approach: innovative glass solutions that deliver well integrity without the baggage of legacy tools

Talk to an Expert

We’re ready to help. Whether you need technical guidance or want to discuss a specific project, our team is just a message away.

Your Questions, Answered

Explore our FAQs to learn more about product performance, installation, standards, and how our glass solutions fit into your operations.